What is Metallurgical Microscope?

A metallurgical microscope is another type of light microscope. These microscopes are different from the typical biological microscopes in that they use the principle of reflected light. They use vertical illumination, and the light source is inserted through a beam splitter into a microscope tube below the eyepiece. Light comes down through the objective and is focused on the specimen through the objective. Light reflected or scattered back to the objective lens is then imaged on the eyepiece.

A metallurgical microscope is another type of light microscope. These microscopes are different from the typical biological microscopes in that they use the principle of reflected light. They use vertical illumination, and the light source is inserted through a beam splitter into a microscope tube below the eyepiece. Light comes down through the objective and is focused on the specimen through the objective. Light reflected or scattered back to the objective lens is then imaged on the eyepiece.

Metallurgical microscopes are used in high-powered microscopes for viewing opaque objects. That is, metallurgy and all kinds of other objects that light cannot pass through (ceramics, plastics, rocks, etc.)

Types of Metallurgical Microscope:

Upright Metallurgical Microscope:

The objective of an upright metallurgical microscope is above the specimen. This is the most commonly used type. The illumination system is also located above the stage, which allows light to be directed from the objective to the specimen and back to the eyepiece. The upright metallurgical microscope can be equipped with a pillar stand or the typical base stand according to the user’s requirements. The typical base stand makes the microscope more stable when it is used to view relatively small specimens. The pillar stand increases the flexibility of the microscope to view specimens of different sizes.

Inverted Metallurgical Microscope:

The objective of an inverted microscope is located below the specimen. It can observe larger specimens. They have a illumination system installed under the stage. This allows light to pass through the objective, reach the specimen, and reflect back to the eyepiece. One of the greatest advantages of this microscope is that it allows for larger specimens that cannot be seen using an upright microscope. This makes them ideal in a number of fields involved in engineering and manufacturing where the microscope serves to investigate cracks or corrosion of fractures.

Illumination about Metallurgical Microscope:

Do you need a metallurgical microscope have reflected illumination only, or it also have reflected and transmitted illumination?

The beam of reflected illumination comes from the top of the object and passes through the objective lens and then hits the object to be inspected. In this way, the objective lens also acts as a condenser. This lighting method is suitable for non-transparent objects such as metals, minerals, etc.

Transmitted illumination often requires backlight measurements. In this setup, a beam of light shines from behind the object, passes through the object, and is picked up by the eyes. It also works well when backlighting an object, creating a well-defined outline that allows for more precise and accurate measurements.

1) Upright Microscopes with reflected light only, which the light come from the top light source and are used on opaque specimen;

2) Upright Metallurgical Microscopes with reflected and transmitted lights, which can emit light from top and bottom light sources. It can be used to examine transparent and opaque specimen.

3) Inverted metallurgical Microscopes which includes a lamp house for reflected illumination.

The higher power of the illumination, the better image of the microscope. The image of the 100W halogen illumination is much better than that of the 30W illumination.

Bright Field and Dark Field:

The metallurgical microscope has many features for a variety of functions. One good example of this is the filter used to change polarization and light intensity to observe different types of specimens.

These features enable users to view different types of objects using both bright and dark field applications.

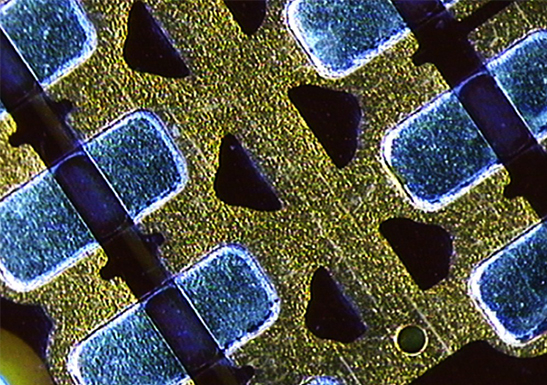

Dark field – This technique is particularly useful for viewing fractures on metal and metallic elements. Here, the dark field element is positioned in the objective head, which causes light to bend from above. This method typically results in a dark field around the specimen.

Dark Field

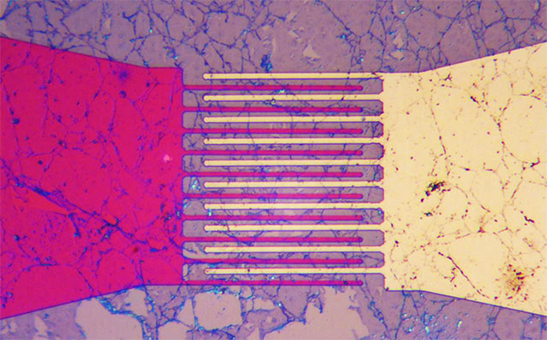

Bright field – This method has been shown to be particularly ideal for viewing alloys (composed of two or more elements). Here, light passes through a polarized lens as well as an analyzer before reaching the sample. Depending on the type of sample, a variety of colors are reflected back to the objective that travels to the eyepieces for viewing.

Bright Field

Metallurgical Microscope’s Objective Lens:

The quality of the objective lens used in the microscope is probably the most critical factor affecting image quality. The objective lens should be properly matched to the eyepiece to obtain the best quality image. Common magnification of metallurgical microscope objective lens is: 5×, 10×, 20×, 50×, 100×.

There are many types of objective lenses of metallurgical microscopes. The infinite plan achromatic, the bright field achromatic objective lens and the dark field achromatic objective lens are common types. Semi-apochromatic, apochromatic is used in advanced microscopes. DIC is suitable for more advanced models and is well suited to observe specimens with subtle convex changes, especially grains and inclusions.

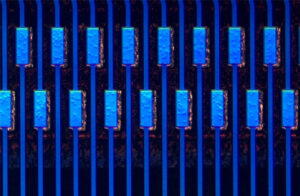

Bright Field Infinite Plan Objective

Bright Field and Dark Field Infinite Plan Objective Semi-apochromatic Plan Objectives

Semi-apochromatic Plan Objectives

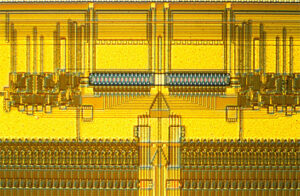

DIC Images

Application of Metallurgical Microscope:

(1) Metallographic inspection of welding;

(2) Metallographic inspection of cast iron;

(3) Quality inspection of heat treatment;

(4) Inspection and evaluation of microstructure of various metal products and raw materials;

(5) Low magnification defect inspection of cast iron, cast steel, non-ferrous metals and raw materials;

(6) Determination of metal hardness (HV, HRC, HB, HL) and grain size rating;

(7) Determination of non-metallic inclusions;

(8) Depth determination of decarbonized layer/carburized hardening layer, etc.

The resources are collected and organized on the Internet, and are only used for learning and communication. If there is any infringement, please contact us to delete.