BSEM-320A Tungsten Filament Scanning Electron Microscope

Introduction

BSEM-320A is a high-performance tungsten filament scanning electron microscope. It has excellent imaging quality capabilities in both high and low vacuum modes. It also has a large depth of field with a user-friendly interface to enable users to characterize specimens and explore the world of microscopic imaging and analysis.

Details

Overview

Packaging & Delivery

Packaging Details:Strong Carton with Polyfoam Protection

Port:Beijing

Lead Time:Within 2-4 Weeks after Receiving Payment

Introduction

BSEM-320A is a high-performance tungsten filament scanning electron microscope. It has excellent imaging quality capabilities in both high and low vacuum modes. It also has a large depth of field with a user-friendly interface to enable users to characterize specimens and explore the world of microscopic imaging and analysis.

Features

1. Low Voltage

Carbon material specimens with shallow penetration depth at low voltage. The true topography of the specimen surface can be obtained with rich details.

Low Voltage-Carbon

Low Voltage-Carbon

High Voltage-Carbon

High Voltage-Carbon

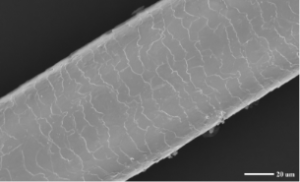

The electron beam irradiation damage of the hair specimen is reduced at low voltage while the charge effect is eliminated.

Low Voltage-Carbon

Low Voltage-Carbon

High Voltage-Carbon

High Voltage-Carbon

2. Expandability

BSEM-320 has a large specimen chamber with an extensive interface: SEM SE\BSE\EDS\EDX\EBSD, etc.

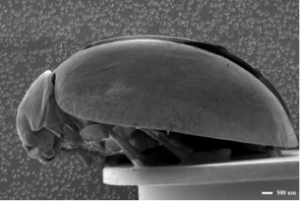

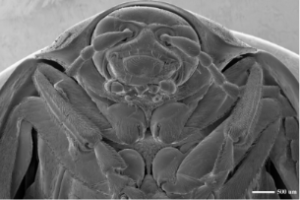

3. Large Field of View

Biological specimens, using a large field of view observation, can easily obtain the overall morphology details of a ladybug’s head, demonstrating cross-scale imaging ability.

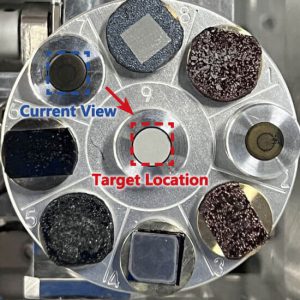

4. Optical Navigation

Quickly locates targeted Region of Interest (ROI). Click where you want to go and see with easy navigation. An in-chamber camera is standard and can take HD photos to help locate specimens quickly.

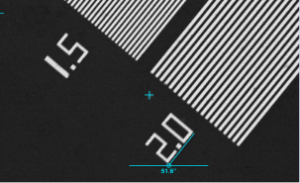

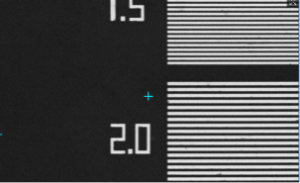

5. Quick Gesture Navigation

Quick navigation by double-clicking to move, middle mouse button to drag, and frame to zoom.

Exp: Frame Zoom – to get a large view of the specimen with low magnification navigation, you can quickly frame the specimen area you are interested in, image zooms in automatically to improve efficiency.

6. Intelligence Assisted Image Astigmatism Correction

Visually display astigmatism within the entire field of view, and quickly adjust to correct by mouse clicking.

7. Auto Focus

One-button focus for fast imaging.

8. Automatic Stigmator

One-click astigmatism deduction to improve work efficiency.

9. Auto Brightness & Contrast

One-click auto brightness & contrast to tune appropriate images’ grayscale.

10. Mixed Imaging (SE + BSE)

Observe the specimen compositional and surface topographic information in one image. The software supports one-click switching between SE and BSE for mixed imaging. Both morphological and compositional information of the specimen can be observed at the same time.

11. Fast Image Rotation Adjustment

Drag a line and release to rotate the image right on the spot.

12. Stage Anti-collision

A multi-way anti-collision solution:

Manually input specimen height: precisely control the distance between the specimen surface and the objective lens.

Image recognition and motion capture: monitor the real-time stage movement.

Hardware: shut down the stage motor at the moment of collision. (BSEM-320A requires this function as an optional feature)

13. Dual Anode (Tetrode)

Dual anode emission system design provides excellent resolution under low landing energy.

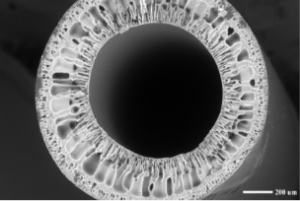

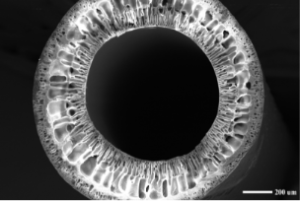

14. Low Vacuum Mode

Provides specimen surface morphology information in low vacuum, switchable vacuum state with one click.

Filtered fiber tube materials are poorly conductive and charge significantly in high vacuum. In the low vacuum, direct observation of non-conductive specimens can be achieved without coating.

Low Vacuum

Low Vacuum

High Vacuum

High Vacuum

Application

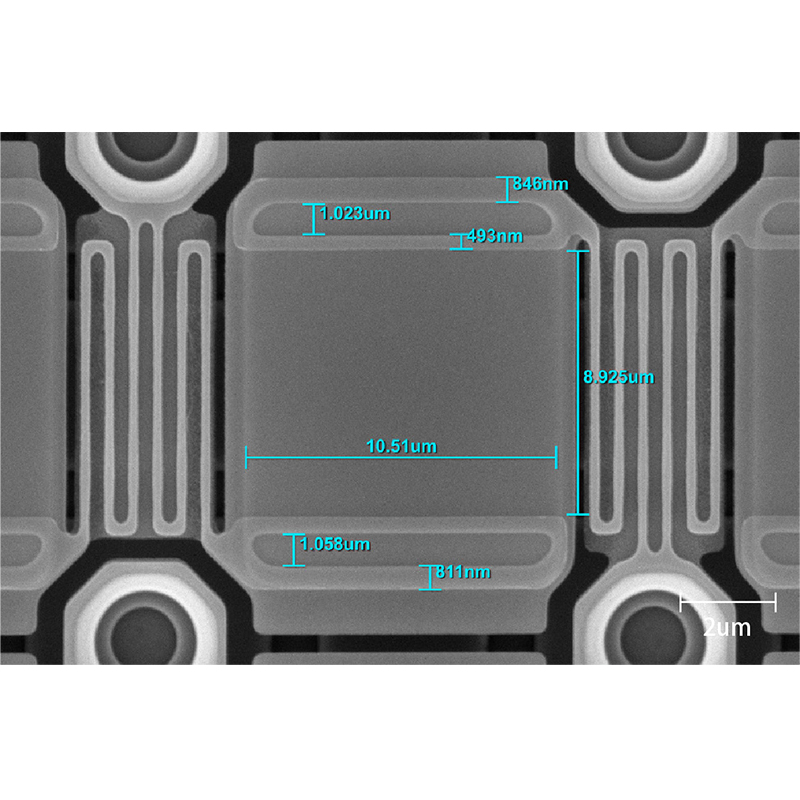

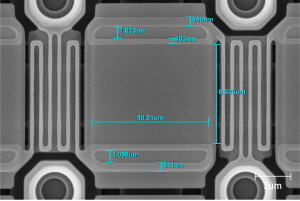

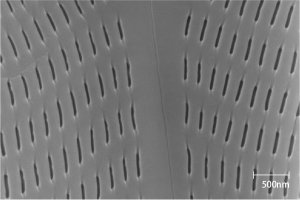

1. Semiconductors and Electronic Component

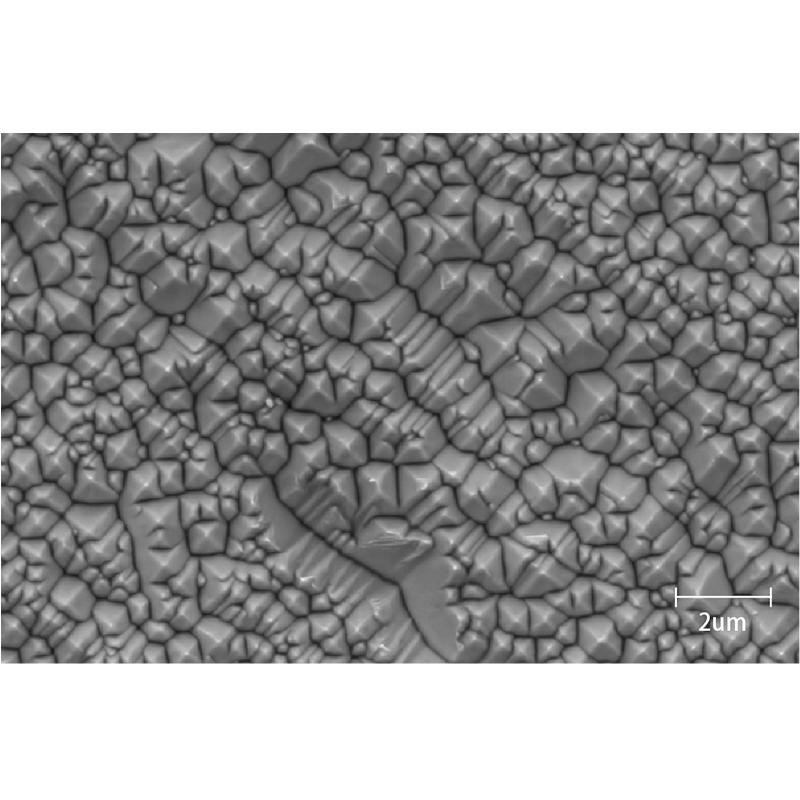

Ordinary Chips-1 / 10kV / ETD

Ordinary Chips-1 / 10kV / ETD

Ordinary Chips-2 / 10kV / ETD

Ordinary Chips-2 / 10kV / ETD

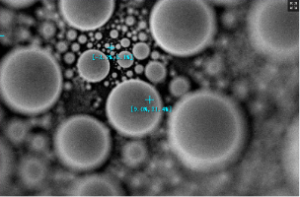

2. Batteries and New Energy

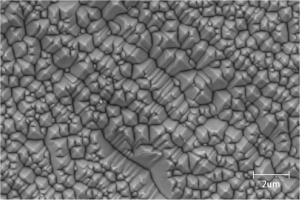

Cathode-Carbon / 5kV / ETD

Cathode-Carbon / 5kV / ETD

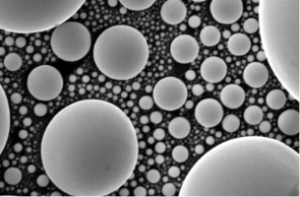

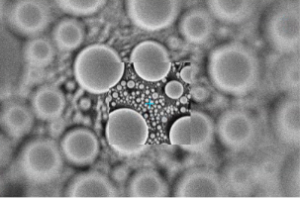

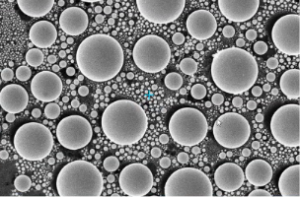

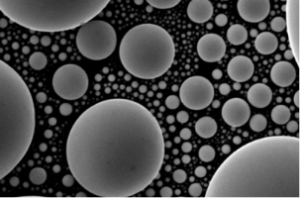

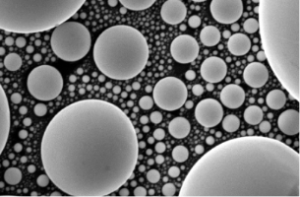

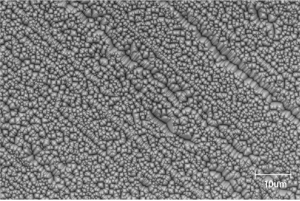

Anode-Lithium Cobaltates / 15kV / ETD

Anode-Lithium Cobaltates / 15kV / ETD

Solar Battery-1 / 5kV / ETD

Solar Battery-1 / 5kV / ETD

Solar Battery-2 / 10kV / ETD

Solar Battery-2 / 10kV / ETD

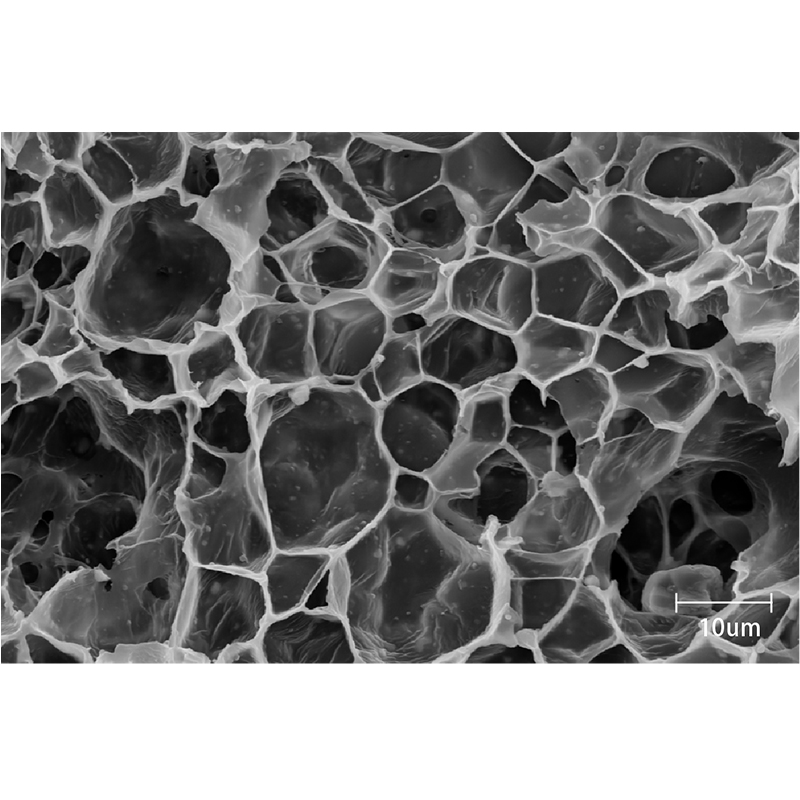

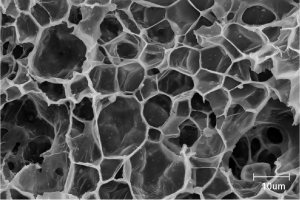

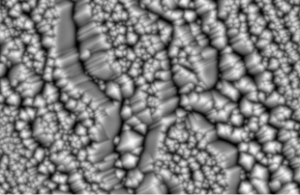

3. Polymer Materials

Polymer Foam / 15kV

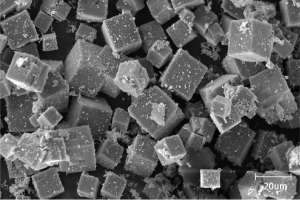

4. Chemicals

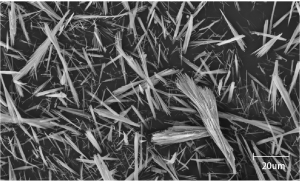

MOF-Material / 15kV / ETD

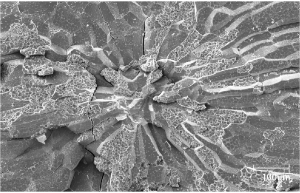

5. ETD Metal

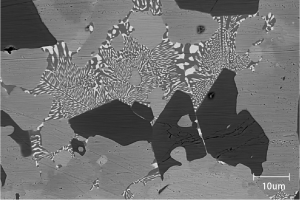

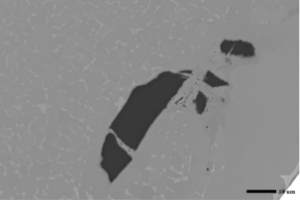

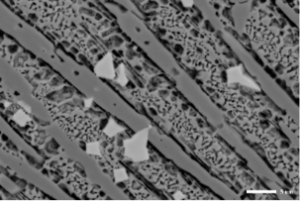

Stainless Steel-Brass Weldments / 15kV / BSED

Stainless Steel-Brass Weldments / 15kV / BSED

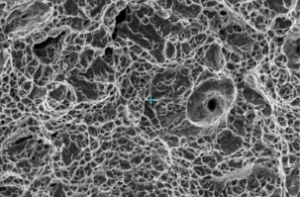

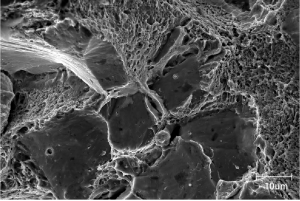

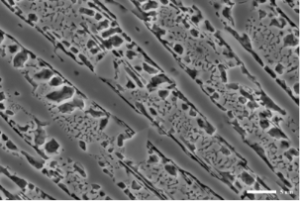

Alloy Fracture Brittleness + Toughness / 20kV / ETD

Alloy Fracture Brittleness + Toughness / 20kV / ETD

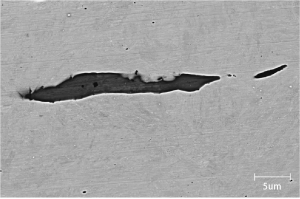

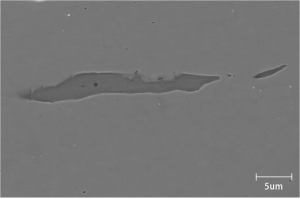

Iron and Steel Inclusions / 15kV / BSED

Iron and Steel Inclusions / 15kV / BSED

Iron and Steel Inclusions / 15kV / ETD

Iron and Steel Inclusions / 15kV / ETD

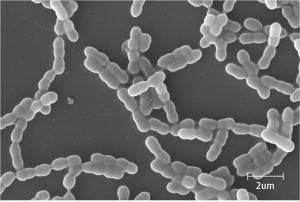

6. Biological

Diatom / 10kV / ETD

Diatom / 10kV / ETD

Staphylococcus Gallinarum / 15kV / ETD

Staphylococcus Gallinarum / 15kV / ETD

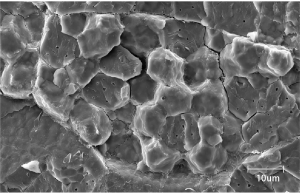

7. Food

Rice / 10kV / ETD

Rice / 10kV / ETD

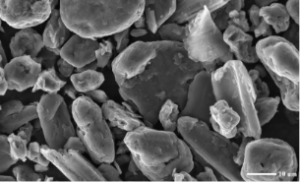

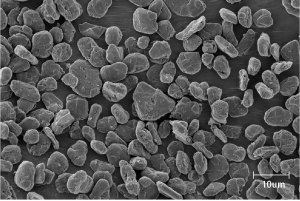

Waxy Rice Starch Granules / 10kV / ETD

Waxy Rice Starch Granules / 10kV / ETD

8. Fundamental Research

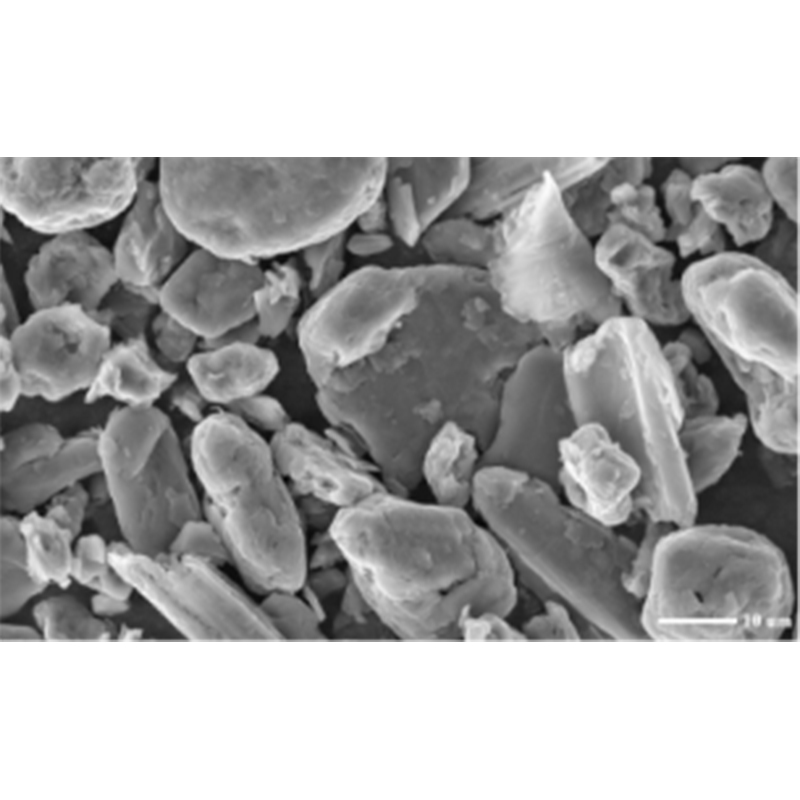

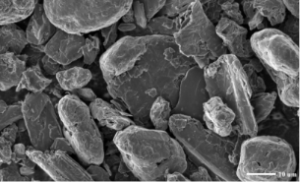

Powder – Magnesium Sulfate / 15kV / ETD

Powder – Magnesium Sulfate / 15kV / ETD

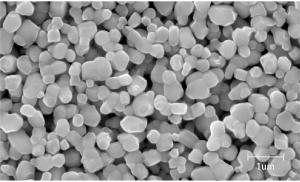

Powder Barium Titanate / 25kV / ETD

Powder Barium Titanate / 25kV / ETD

Specification

|

Item |

Specification |

BSEM-320A |

BSEM-320B |

||

|

Electron Optical System |

Pre-aligned Medium-sized Hairpin-type Tungsten Filament |

● |

● |

||

|

Resolution |

High Vacuum: 3nm@30kV (SE), 4nm@30kV (BSE), 8nm@3kV (SE) |

● |

● |

||

|

Low Vacuum: 3nm@30kV (SE) |

○ |

○ |

|||

|

Magnification:1-300,000x (film), 1-1000,000x (screen) |

● |

● |

|||

|

Accelerating voltage: 0.2kV-30kV |

● |

● |

|||

|

Imaging System |

Everhart-Thornley Detector (ETD) |

● |

● |

||

|

Backscattered electron detector (EBSD) |

○ |

○ |

|||

|

Low vacuum secondary electron detector |

○ |

○ |

|||

|

Energy spectrometer EDS |

○ |

○ |

|||

|

BSE |

○ |

○ |

|||

|

Vacuum System |

High vacuum: better than 5*10-4Pa |

● |

● |

||

|

Low vacuum: 5-1000Pa |

○ |

○ |

|||

|

Control Mode: Fully automatic. Turbo molecular pump:>240L/s. Mechanical pump: 200L/min (50Hz) |

● |

● |

|||

|

Specimen Chamber |

Camera |

Optical Navigation |

● |

● |

|

|

Monitoring in the Specimen Chamber |

● |

● |

|||

|

Specimen Table |

Three Axis Automatic |

● |

|

||

|

Five Axis Automatic |

|

● |

|||

|

Stage Range |

X: 120mm. Y: 115mm. Z: 50mm. |

● |

|

||

|

X: 120mm. Y: 115mm. Z: 50mm. R: 360° T: -10°- +90° |

|

● |

|||

|

Software |

Windows. Optical Navigation, Gesture Quick Navigation. Auto Brightness & Contrast, Auto Focus, Automatic Stigmator and Intelligence Assisted Image Astigmatism Correction |

● |

● |

||

|

Large-FOV Image Stitching |

○ |

○ |

|||

|

Installation Requirements |

Space: L≥ 3000 mm, W ≥ 4000 mm, H ≥ 2300 mm Temperature: 20°C (68°F) ~ 25°C (77°F) Humidity: ≤ 50 % Power Supply: AC 220 V(±10 %), 50Hz, 2kVA |

● |

● |

||

Note: ● Standard Outfit, ○ Optional

Accessories

The scanning electron microscope (SEM) is used not only for the observation of surface morphology but also for the analysis of the composition of micro-regions on the specimen surface.

BSEM-320 has a large specimen chamber with an extensive interface. In addition to supporting conventional Everhart–Thornley detector (ETD), Backscattered-Electron detector (BSE), and Energy-dispersive X-ray spectroscopy (EDS/EDX), various interfaces such as Electron Backscatter Diffraction Pattern (EBSD) and Cathodoluminescence (CL) are also reserved.

1. Backscattered-Electron Detector (BSE)

Comparison of secondary electron imaging and backscattered electron imaging

In the backscattered electron imaging mode, the charge effect is significantly suppressed and more information on the composition of the specimen surface can be observed.

Plating Specimens:

Tungsten Steel Alloy Specimens:

2. Four-quadrants Backscattered Electron Detector – Multi-channel Imaging

The detector has a compact design and high sensitivity. With the 4-quadrants design, it is possible to obtain topographic images in different directions as well as composition distribution images without tilting the specimen.

Component Images

Component Images

Four One-channel Images

Four One-channel Images

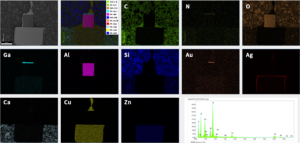

3. Energy Spectrum

LED small bead energy spectrum analysis results.

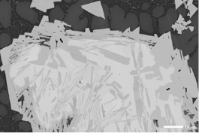

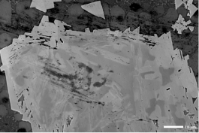

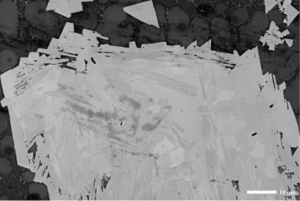

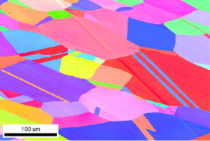

4. Electron Backscatter Diffraction Pattern (EBSD)

The tungsten filament electron microscope with a large beam current fully meets the testing requirements of high-resolution EBSD and can analyze polycrystalline materials such as metals, ceramics, and minerals for crystal orientation and grain size analysis.

The figure shows the EBSD grain map of Ni metal specimen, which can identify grain size and orientation, determine grain boundaries and twins, and make accurate assessments of material organization and structure.