BS-6034A Inverted Metallurgical Microscope

Introduction

The BS-6034 series inverted metallographic microscope can place samples above the objectives and observe them from below, and is widely used in industries such as steel, automotive, machinery and electronics.

Details

Overview

Packaging & Delivery

Packaging Details:Strong Carton with Polyfoam Protection

Port:Beijing

Lead Time:Within 1-2 Weeks after Receiving Payment

Introduction

Introduction

The BS-6034 series inverted metallographic microscope can place samples above the objectives and observe them from below, and is widely used in industries such as steel, automotive, machinery and electronics. In cases where the sample is uneven or has a large volume, placing the sample on a platform can facilitate and facilitate quick observation. BS-6034 can be used for large and heavy samples weighing less than 5kg, suitable for magnification observation ranging from tens to thousands of times. BS-6034A is for bright field and simple polarizing observation, while BS-6034B is for bright field, dark field and simple polarizing observation.

Features

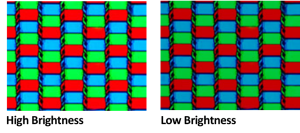

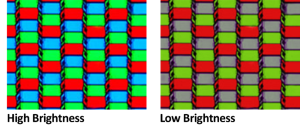

LED illumination

LED illuminator provides illumination for observation methods such as bright field, oblique lighting, and polarizing, with adjustable color temperature. It can provide true color images at all brightness levels. It has long service life, no need to frequently replace light bulbs. Low heat generation, no risk of overheating, no need for a cooling fan, creating a quiet and interference free working environment. Due to the various advantages of LED lighting sources, they are replacing traditional halogen light sources and becoming the preferred light source for microscopes.

LED light source

Halogen light source

LED illuminator of BS-6034A

LED illuminator of BS-6034B

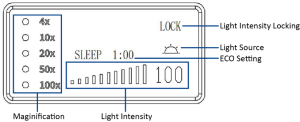

Microscope status display function

The LCD screen at the front of the microscope can display the usage status of the microscope, including magnification, light intensity, standby mode, etc.

Brightness memory function

It can remember the illumination brightness of using each objective and automatically adjust the light intensity to the corresponding brightness of each objective when different objectives are converted to each other, reducing visual fatigue and improving work efficiency.

4X

20X

50X

100X

Realize observation of large volume samples

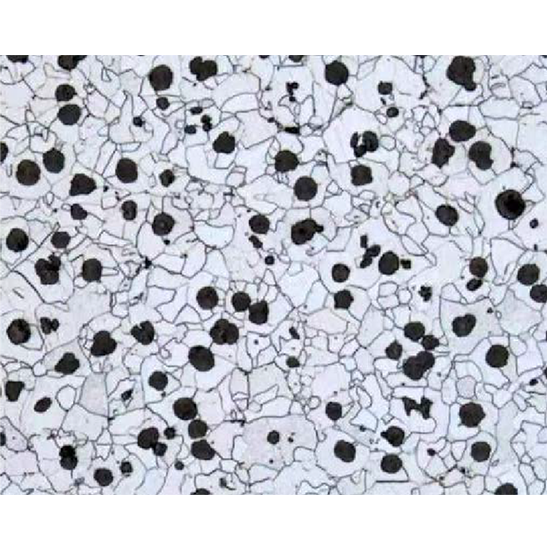

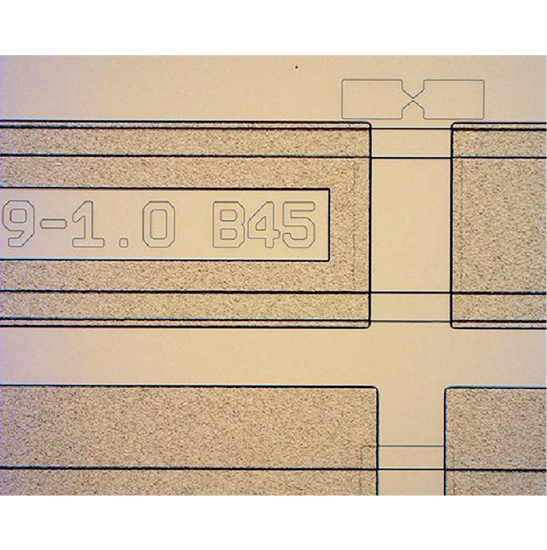

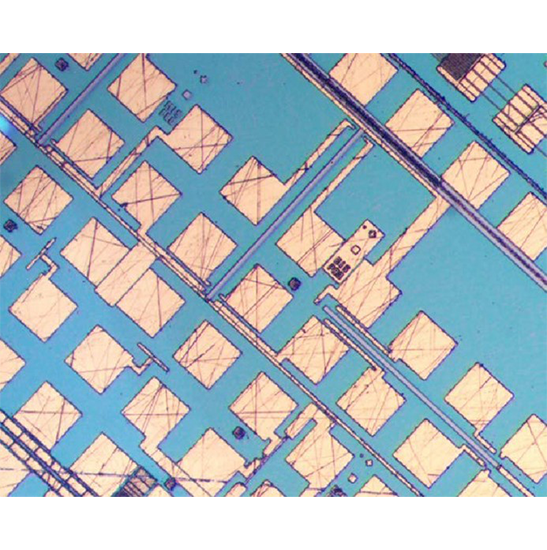

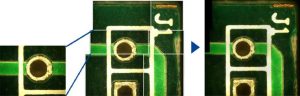

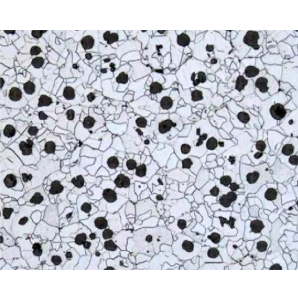

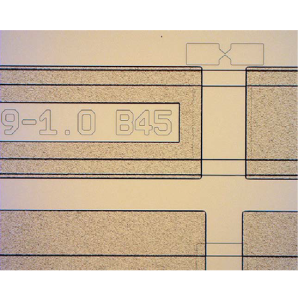

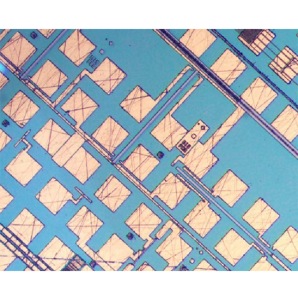

The research samples for metal corrosion, metal flow, or carburizing are relatively large in volume, and the samples for wafer and integrated circuit packaging testing are often large in area. Traditional metallographic microscopes are difficult to observe the complete metallographic structure.

The spacious workspace is suitable for placing large and heavy samples. The surface of the stage is scratch resistant and suitable for observing materials of various materials and shapes. At the same time, there are various supporting platform pallets and gaskets. The gaskets with different shapes and apertures can meet the observation and analysis of various small-sized samples. The flexible low position handle combines the accuracy and comfort of sample movement observation.

HDR image

Metallographic samples often have uneven surfaces and severe reflection, which makes it difficult to observe subtle material structures and defect states during observation. The image quality of unclear crystal texture and surface state may affect the judgment of acceptance and measurement results.

By using HDR mode, it is easy to observe the dazzling crystal parts in the metallographic structure that are difficult to observe with conventional mode, improving the accuracy of the image, reducing misjudgment, and increasing the reliability of the measurement.

Dazzling high reflective image

HDR image

Deth of field fusion and 3D reconstruction

The software provides depth of field fusion and 3D reconstruction functions, both of which can be used in real-time HDR mode. After using the depth of field fusion function, users will receive a 3D reconstructed model that can be imported and displayed in the 2.5D module.

Depth of field fusion

Different depth of field leads to unclear imaging in some area

Large scale panoramic imaging

Samples in certain specific fields require observation through enlarged images of large areas. For example, in metallurgical inspections, in order to have a more comprehensive understanding of the effects of different techniques, the overall metal flow and carburizing conditions of the samples are usually checked. With the image processing software, multiple images can be stitched together by manually moving the stage to get high magnification and wide field of view imaging. This feature allows for easy acquisition of large-area images, significantly reducing the time and effort required.

Specification

|

Item |

Specification |

BS-6034A |

BS-6034B |

|

|

Optical System |

Infinity Color Correction Optical System |

● |

● |

|

|

Viewing Head |

45° inclined, gemel binocular head, interpupillary distance: 48-75mm. eyepiece tube Φ30mm, fixed diopter. |

● |

|

|

|

5°-35° inclined, gemel binocular head, interpupillary distance: 48-75mm. eyepiece tube Φ30mm, fixed diopter. |

|

● |

||

|

Eyepiece |

Eyepiece SW10X/22mm, with diopter adjustment -5~+5 |

● |

● |

|

|

Objectives |

Plan Achromatic Metallurgical Objectives |

4X |

○ |

○ |

|

10X |

○ |

○ |

||

|

20X |

● |

○ |

||

|

50X |

● |

○ |

||

|

100X |

● |

○ |

||

|

Plan Semi-Apochromatic Metallurgical Objectives |

5X |

● |

○ |

|

|

Bright & Dark Field Metallurgical Objectives (objective diameter 200mm, focal distance 45mm, objective interface 26) |

5X/NA=0.12, WD=20mm |

|

● |

|

|

10X/NA=0.30, WD=11mm |

|

● |

||

|

20X/NA=0.45, WD=3.1mm |

|

● |

||

|

50X/NA=0.80, WD=1.0mm |

|

● |

||

|

100X/NA=0.90, WD=1.0mm |

|

○ |

||

|

Stage & Accessories |

Double-layer stage, stage size: 226mm*178mm, travel range: 50mm*50mm. |

● |

● |

|

|

Slide clip |

● |

● |

||

|

Stage holder (Φ10) |

● |

● |

||

|

Stage holder (Φ15) |

● |

● |

||

|

Stage holder (Φ25) |

● |

● |

||

|

Single layer fixed stage |

○ |

○ |

||

|

Culture dish holder, Terasaki |

○ |

○ |

||

|

Culture dish holder, Φ90mm |

○ |

○ |

||

|

Culture dish holder, Φ65mm |

○ |

○ |

||

|

Ground glass plate, Φ110mm |

○ |

○ |

||

|

Extension attachment |

○ |

○ |

||

|

Mechanical ruler, travel range: 128mm(X)*80mm(Y) |

○ |

○ |

||

|

Universal holder |

○ |

○ |

||

|

Microscope Body & Nosepiece |

Bright field microscope frame. Coarse and fine coaxial focusing system, with elastic adjustment device on the right. Coarse travel range 37.7mm, fine precision 0.002mm. The lifting range is 6mm above the focal point. Quintuple nosepiece. LCD screen displaying objective magnification, aperture, Sleep mode, lock, brightness, color temperature and timing. Motorized aperture. |

● |

|

|

|

Bright & dark field microscope frame. Coarse and fine coaxial focusing system, with elastic adjustment device on the right. Coarse travel range 37.7mm, fine precision 0.002mm. The lifting range is 6mm above the focal point. Quintuple nosepiece. LCD screen displaying objective magnification, aperture, Sleep mode, lock, brightness, color temperature and timing. Motorized aperture. |

|

● |

||

|

Polarizer & Analyzer |

Polarizer, rotatable |

○ |

● |

|

|

Analyzer |

○ |

● |

||

|

Filters |

Blue filter |

○ |

● |

|

|

Green filter |

○ |

● |

||

|

Yellow filter |

○ |

● |

||

|

Ground glass filter |

○ |

● |

||

|

Illumination |

3W LED, color temperature adjustable |

● |

● |

|

|

DC 24V 2.5A adapter |

● |

● |

||

|

C-mount Adapter |

0.5X C-mount adapter |

○ |

○ |

|

|

0.7X C-mount adapter |

○ |

○ |

||

|

1X C-mount adapter |

● |

● |

||

|

Package |

Paper box with pearl cotton (single unit packaging) |

● |

● |

|

Note: ● Standard Outfit, ○ Optional

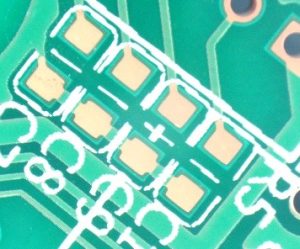

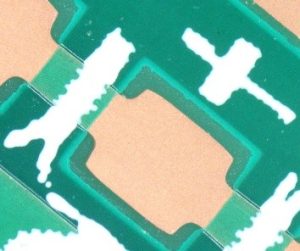

Sample Image

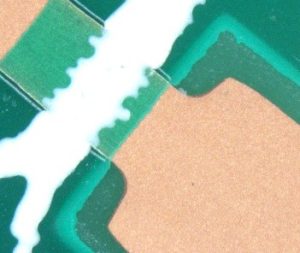

Carburized Metal

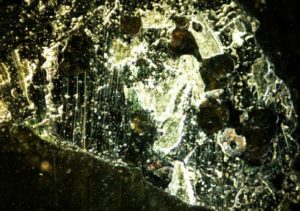

Wafer

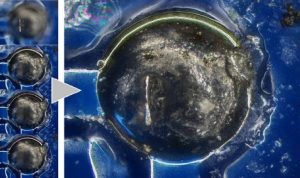

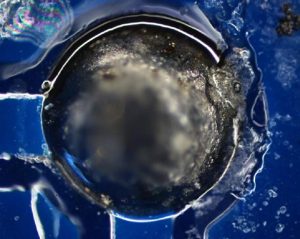

Microchip

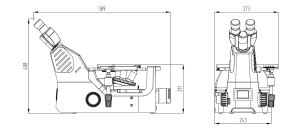

Dimension

BS-6034A

Unit:mm