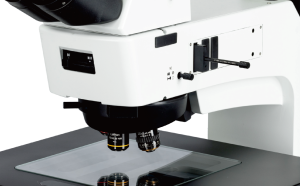

BS-4050NIR Near-Infrared Industrial Inspection Metallurgical Microscope

Introduction

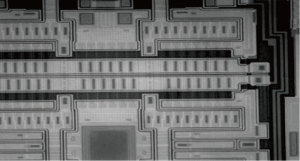

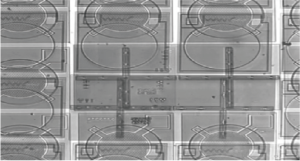

BS-4050NIR has wide-field illumination, area array detection to achieve wide spectrum, large field of view and high-resolution imaging. Real-time imaging and observation of packaged chips and the interior of wafers provide users with clearer ultra-wide spectrum imaging.

Details

Overview

Packaging & Delivery

Packaging Details:Strong Carton with Polyfoam Protection

Port:Beijing

Lead Time:Within 4-5 Weeks after Receiving Payment

Introduction

BS-4050NIR near-infrared industrial microscope imaging system is leading industrial infrared inspection equipment, providing efficient industrial testing solutions for customers. BS-4050NIR has wide-field illumination, area array detection to achieve wide spectrum, large field of view and high-resolution imaging. Real-time imaging and observation of packaged chips and the interior of wafers provide users with clearer ultra-wide spectrum imaging. The infrared band (900-1700nm) has a wide spectral range, small scattering and strong penetration into silicon wafers (Germanium wafers). The large numerical aperture objective lens (with correction ring) can eliminate aberrations caused by difference in overlay thickness, achieving effective and accurate infrared detection. Ergonomics design provide users with the highest working efficiency.

Features

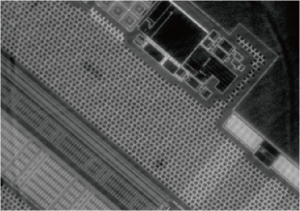

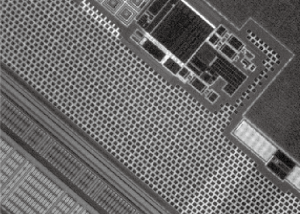

1.Wide spectrum dedicated infrared camera

BS-4050NIR uses a wide spectrum dedicated infrared camera, covering bright field and infrared observation, for field illumination, wide imaging field and infrared observation. Field illumination, wide imaging field of view and high resolution. With bandpass color filter for area array detection, it can respond to different parts of the chip inside the silicon wafer to meet the needs of different customers.

3.2 mega pixel

1.3 mega pixel

2.Epi-illuminator

The optical elements in illuminators are enhanced transparency in the 400-1700nm band. There are bright field and infrared field for selection. Wide spectral range, small scattering and strong penetrability to silicon wafers (Germanium sheet).

Automatic matching of aperture diaphragm and objective magnification, no need for manual adjustment, it is faster and more efficient for different users to have the same observation effect.

3.Special infrared objective lens

BS-4050NIR industrial infrared microscope imaging system is equipped with 5X-50X professional infrared objectives that provide aberration correction from visible to near-infrared wavelengths, suitable for conventional bright field and dedicated infrared observation.

For high magnification objectives with larger numerical apertures, a correction ring is added to correct aberrations caused by difference in overlay thickness, to enable high-definition and accurate detection in the near-infrared band.

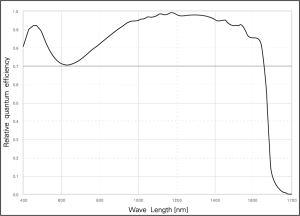

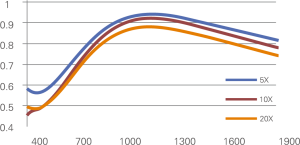

Infrared objective lens transmittance curve

4.Multi-hole filter slider

Multi-hole filter sliders, there are 1100nm, 1200nm, 1300nm bandpass near-infrared color filters for option. Users can quickly switch bands. By narrow-bandwidth secondary filtering to achieve responses of different structures, high-definition images can be obtained.

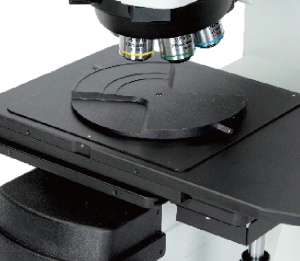

5.Large mechanical stage

BS-4050NIR industrial infrared microscope imaging system uses a clutch button. The users can flexibly move the stage by pressing the clutch button, without the need for prolonged gripping of the handle, and press the clutch button to cancel the quick move. Free the hands of users during long-term operation and speed up observation. The stage has precision rail mechanism, which makes the movement lighter and smoother, and the product more stable and reliable.

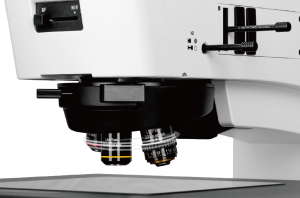

6.Safe, high speed motorized nosepiece

Equipped with forward and backward moving modes to quickly and accurately locate the required magnification objective with high precision in repeated positioning. Mechanical switching mode effectively improves the working life of the nosepiece.

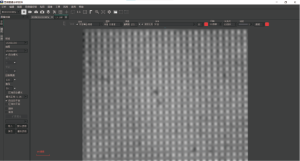

7.Software with more operating functions

In addition to functional modules such as management, measurement, image collection, and layer management, additional with the unique infrared image enhancement function, automatic detection functions can also be specified according to customer needs.

Image enhancement

Improve the image clarity of infrared penetration, making local details more obvious.

AI software empowerment

AI Self-learning function can be performed based on the defects of the samples, automatic defect identification, capture, counting statistics and other functions. Also, customization can be made according to the needs of different customers.

Specification

|

Item |

Specification |

BS-4050NIR |

|

|

Optical System |

Infinite Color Corrected Optical System |

● |

|

|

Viewing Head |

Near-infrared 30° tilting trinocular head, erect image, interpupillary distance: 50-76mm, splitting ratio:100:0 or 0:100 |

● |

|

|

Eyepiece |

High eye point wide field plan eyepiece PL10X/23mm, with adjustable diopter |

● |

|

|

High eye point wide field plan eyepiece PL10X/23mm, with micrometer and adjustable diopter |

○ |

||

|

10X/22mm, with adjustable diopter |

○ |

||

|

10X/22mm, with micrometer and adjustable diopter |

○ |

||

|

Objective |

Plan Semi-Apochromatic NIR Objectives

|

5X/NA=0.15, WD=19.5mm, 450-1700nm |

● |

|

10X/NA=0.3, WD=12.2mm, 450-1700nm |

● |

||

|

20X/NA=0.45, WD=7.31-7.57mm, correction collars: 0-1.2mm, 450-1700nm |

● |

||

|

50X/NA=0.7, WD=2.68-2.93mm, correction collars: 0-1.2mm, 450-1700nm |

● |

||

|

Nosepiece |

Sextuple bright field nosepiece, with DIC slot |

● |

|

|

Stage |

8 inches three-layer mechanical stage with low position coaxial adjustment, size: 525mm*330mm, moving range: 210mm*210mm, with clutch handle for quick movement. Glass plate for reflected use. |

● |

|

|

6 inches double-layer mechanical stage with low position coaxial adjustment, size: 525mm*240mm, moving range: 445mm*240mm, with clutch handle for quick movement. Glass plate for and reflected use. |

○ |

||

|

Frame |

Reflected frame with low position coaxial focusing mechanism, coarse range: 35mm, fine precision: 0.001mm. Built-in 100-240V wide voltage system, with brightness setting button and reset button. |

● |

|

|

Illumination |

Bright field NIR reflected illuminator, with electric variable aperture diaphragm, center adjustable; with switch device for bright field and NIR; with filter slot; with MvImage-Industry software and Dongle. |

● |

|

|

NIR Halogen light box, 12V/100W, with center set, for transmitted and reflected use |

● |

||

|

Halogen light, 12V/100W |

● |

||

|

Camera |

1.3 mega-pixel NIR camera (400-1700nm), monochrome camera, InGaAs, frame rate 125fps@1280*1024, Camera Link, pixel size 5μm |

○ |

|

|

3.2 mega-pixel NIR camera (400-1100nm), monochrome camera, Sony IMX 252, frame rate 120fps@2064*1544, USB 3.0, pixel size 3.45μm |

● |

||

|

Filter |

1100nm band-pass near-infrared filter |

● |

|

|

1200nm band-pass near-infrared filter |

○ |

||

|

1300nm band-pass near-infrared filter |

○ |

||

|

PC |

LENOVO M90T (i5-9500 16G 1T + 256G 2G discrete graphics card) + 23-inch monitor |

● |

|

|

Software |

MvImage-Industry: Real-time image collection, image photography, and video recording, with dynamic and static resolutions that can be dynamically switched. Automatic exposure, automatic white balance, brightness adjustment, gain adjustment, gamma adjustment, mirroring and inversion. Z-stack and delayed collection. Morphological measurement and scale annotation, the measurement data can export. Automatic edge finding measurement, real-time enhancement of preview images. PC software can control the electric functions of the microscope (nosepiece, light shutter and light brightness) |

● |

|

|

Adapter |

1X C-mount adapter, focus adjustable |

● |

|

|

Other Accessories |

Microscope objective micrometer, reticle, metallographic correction film, stage micrometer 0.01mm |

● |

|

|

Internal hexagonal Spanner M4 |

● |

||

|

Internal hexagonal Spanner M4 (seven shaped) |

● |

||

Note: ● Standard Outfit, ○ Optional

Application

Non-destructive inspection for CSP/SIP

Non-destructive analysis of bad chip packaging

Near infrared detection of MEMS devices