BAWL-06 Wafer Inspection System

Introduction

The BAWL-06 features and excellent optical imaging system, enabling high-definition capture of micro details on wafers. With a versatile macro inspection module and a flexible and easy-to-use remote-control joystick, it enables multi-angle, full-field macro inspection, making it an efficient tool for wafer defect analysis.

Details

Overview

Packaging & Delivery:

Packaging Details:Strong Carton with Polyfoam Protection

Port:Beijing

Lead Time:Within 2-4 Weeks after Receiving Payment

Introduction

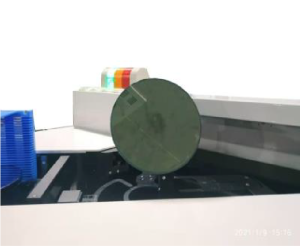

Equipped with a fully automated wafer handling system, achieving efficient macro/micro inspection. The BAWL-06 features and excellent optical imaging system, enabling high-definition capture of micro details on wafers. With a versatile macro inspection module and a flexible and easy-to-use remote-control joystick, it enables multi-angle, full-field macro inspection, making it an efficient tool for wafer defect analysis.

Feature

1.EFEM system

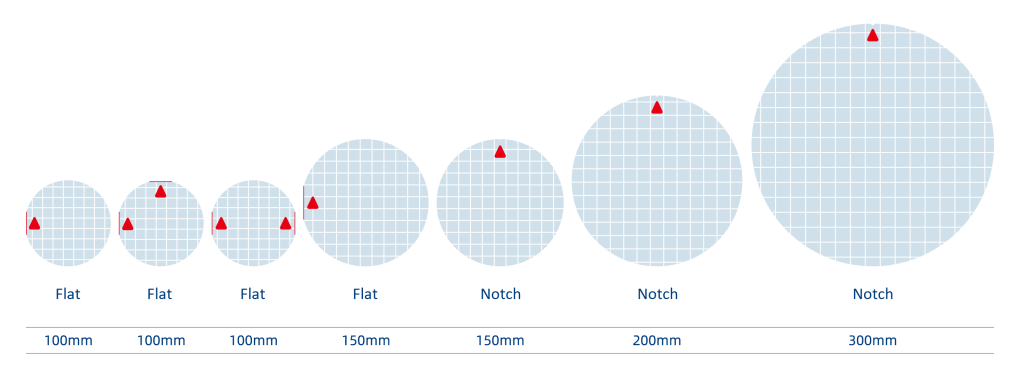

The EFEM system is equipped with automatic loading and unloading modules and is compatible with various wafer sizes. It is an essential component of wafer inspection equipment. In a highly clean environment, individual wafers are transferred to the inspection module through a precision mechanical arm. The core components include the loadport, wafer transport robot, and wafer aligner.

Open Cassette

2.Mapping

Using a high-precision optical detection system, wafers are scanned layer by layer to record wafer position information. It can quickly and accurately identify tilted or misaligned wafers and provide alarms for abnormal states, achieving 100% accuracy.

Cassette Mapping: Standard

Oblique Insertion

3.High-precision wafer pre-alignment

A non—contact optical method is used to locate the center and notch/flat of the wafer.

The fully automated intelligent pre-alignment mechanism achieves accurate and fast positioning of the inspection target. It’s more efficient in operation and more precise in data collection.

Suitable for various wager materials such as Si, SIC, EMC, Glass, etc.

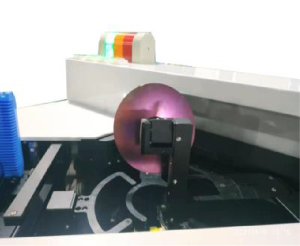

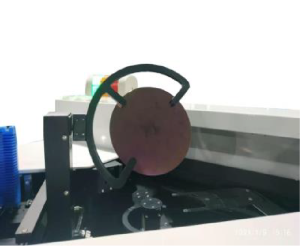

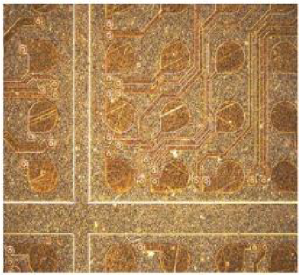

4.Macro Inspection

The BAWL series includes a macro inspection are that can perform a 360° rotation for macro inspection of wafer surfaces and backs, making it easy to detect defects and particles on the front, black, and edge sides of the wafer. The wafer can be tilted for observation using the control lever. By rotating and tilting the wager at multiple angles, the entire front, back, and edge of the wafer can be visually inspected. Various light sources, including yellow and green, are available to accommodate different working conditions.

Surface macro inspection

Edge inspection

Backside inspection

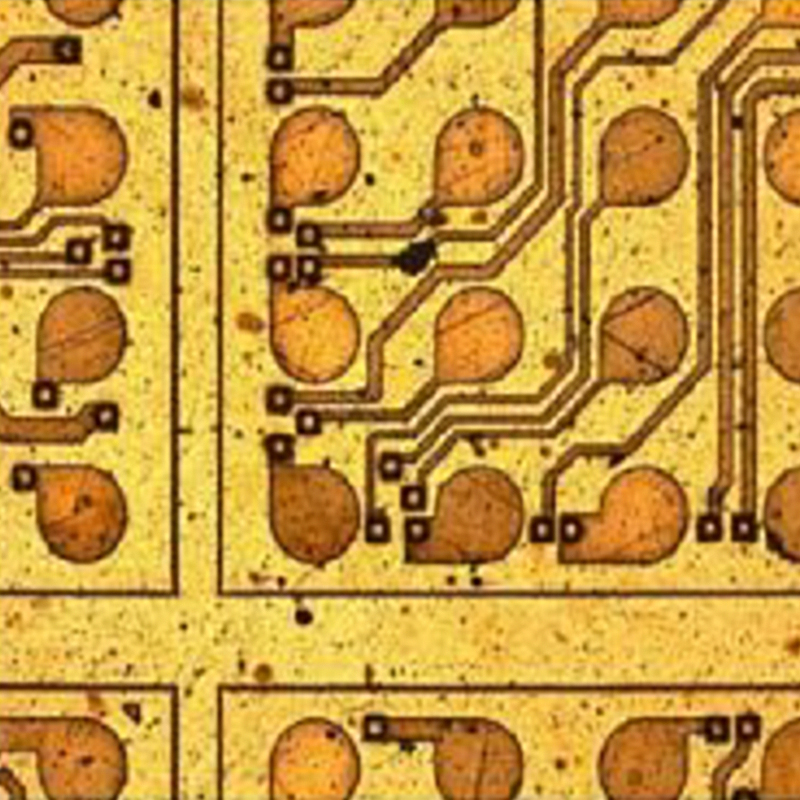

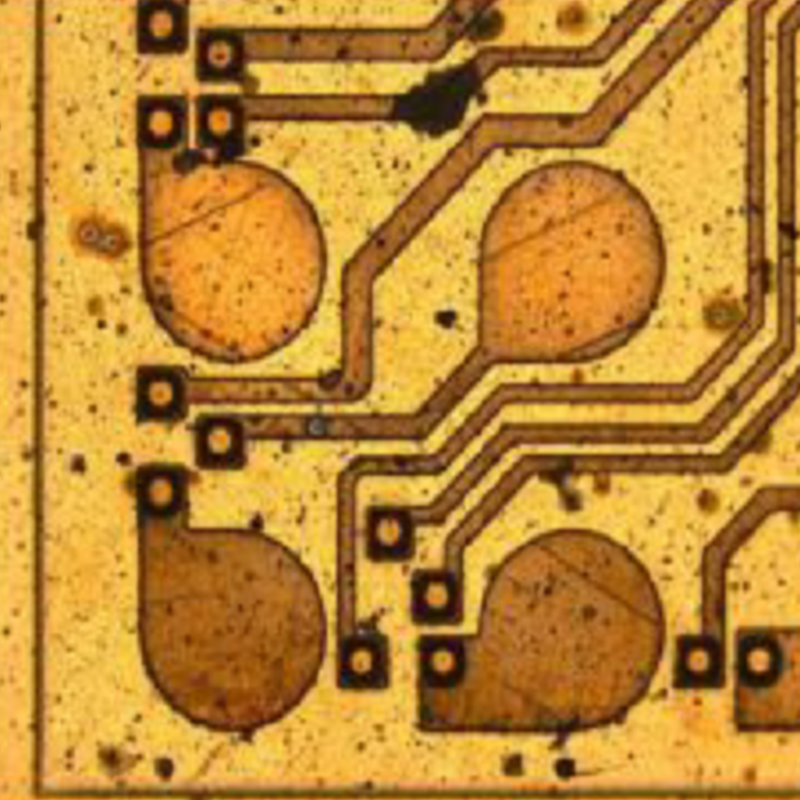

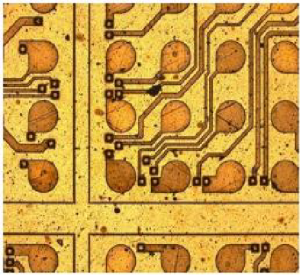

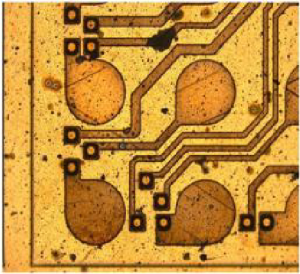

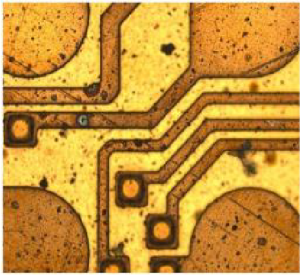

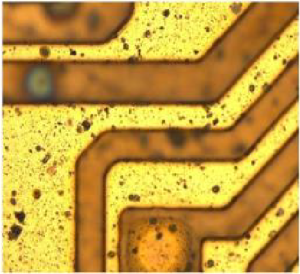

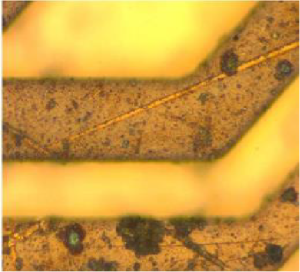

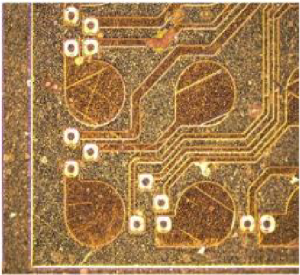

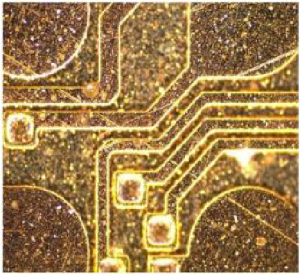

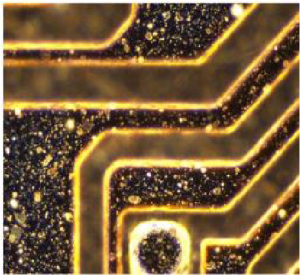

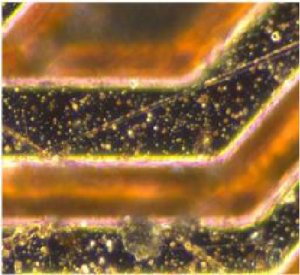

5.Precision optical micro inspection

Using a wide-beam imaging system, it supports a world-leading ultra-wide field of view of 25mm, providing a new experience of large-field vision.

The optical system is equipped with a polarizing system with polarizing and differential interference contrast imaging systems for high contrast, high-resolution micro-imaging.

5X Bright Field

10X Bright Field

20X Bright Field

50X Bright Field

100X Bright Field

5X Dark Field

10X Dark Field

20X Dark Field

50X Dark Field

100X Dark Field

6.Precision optical electric components

The equipment’s objective and aperture diaphragm are controlled by an automatic electric control system. The control buttons are in front of the equipment platform, making them easily accessible.

The user-friendly electric design not only avoids frequent manual operations but also make your inspection work more precise and flexible. Controls within reach, helping you improve efficiency.

7.Professional APO objective with infinite long working distance

The long working distance BD plan semi-apochromatic metallurgical objectives satisfy observation methods such as bright field, dark field, polarization and DIC. The brightness enhancement of the image in the dark field improves the detection ability of the sample. This series of objective strictly selects high transmittance lenses and advanced coating technology to truly restore the natural color of the sample. The bright and dark field objective is made of special process materials, which greatly reduces weight and contributes to preventing environmental pollution and improving the controllability of objective conversion. The semi-apochromatic design has excellent color correction performance, improving the contrast and clarity of observed images. Long working distance objective lenses are widely used in various testing fields, easily achieving non-destructive testing.

8.Advanced image analysis software

The image processing software, equipped with hardware accessories such as electric platform, electric Z-axis, electric converter, and light source control, supports automatic large image stitching, depth fusion, automatic focusing, 3D measurement, and is compatible with 64-bit Windows systems.

Functions including: auto focus, light source control, electronic control function, measurement module, image library management, depth fusion, particle counting, image stitching, 3D view, 3D measurement.

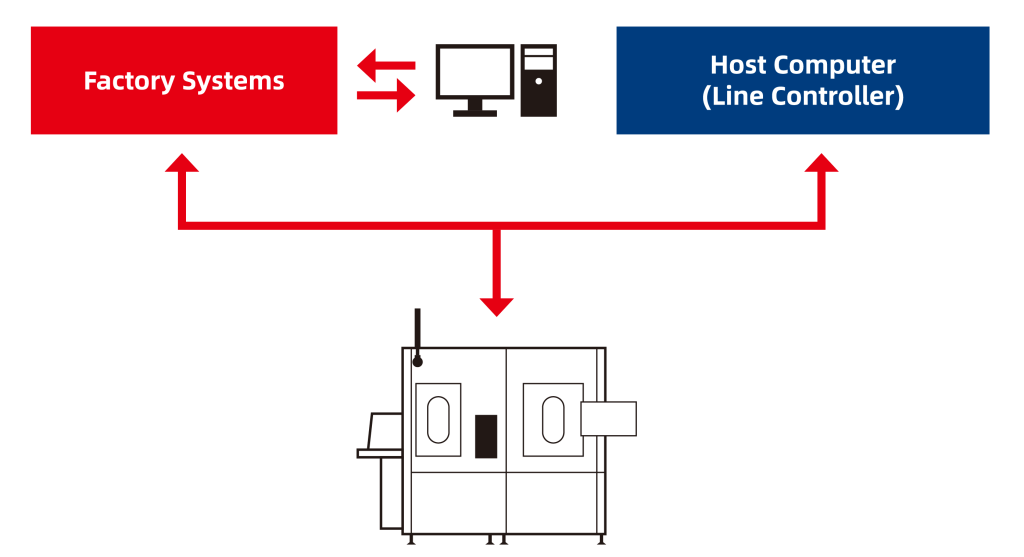

9.Data communication system

The wafer inspection system supports the SECS/GEM semiconductor standard communication protocol, acting as a communication bridge between the equipment and customer MES and other host systems, enabling functions such as work order issuance, material accounting, process recording, and remote control.

The system is equipped with a user-friendly human-machine interface system, making it easy to operate and monitor wafer workstations in real time.

It can recognize various wafer cassette types and is equipped with a high-precision wafer OCR reader. With the unique ID of each wafer, it monitors the entire process data of the wafer. It allows data extraction, modification, and change of the inspection work more efficient and reliable.

The system is compatible with power outage protection devices, allowing the equipment to maintain IPC system operation for 15 minutes in case of power outage, providing enough time for data saving.

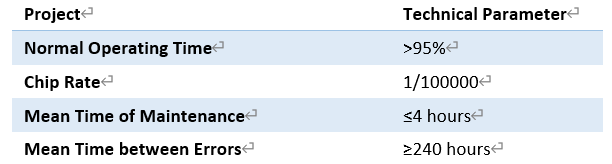

10.Reliability

The BAWL series wafer inspection system has high stability and transmission rate. The system uses a safety design compliant with SEMI standards, with built-in UPS uninterruptible power supply, a vacuum holding system, an efficient and stable dual-arm mechanical arm, and various safety interlock functions. It safely and reliably places wafer or warped wafers at various equipment workstation sites.

Specification

|

Item |

Specification |

BAWL-06 |

BAWL-08 |

|

Wafer Size |

100mm/150mm |

● |

|

|

150mm/200mm |

|

● |

|

|

Minimum Wafer Thickness |

150um |

● |

|

|

150um/180um |

|

● |

|

|

Type of Cassette |

Open Cassette/Smif Pod |

● |

● |

|

Inspection Mode |

Select All/Odd/Even/Manual Setting |

● |

● |

|

Cassette Mapping |

Standard |

● |

● |

|

Convex detection and warning in Cassette |

≥4mm |

● |

● |

|

Pre-Aligner Function |

Flat/Notch |

● |

● |

|

Pre-Aligner Type |

Non-contact positioning flat edge/notch, supporting 0 °, 90 °, 180° and 270 ° orientation settings |

● |

● |

|

Macro Inspection |

Top surface/Edge/Backside |

● |

● |

|

Device dimension |

1450mm(W)*700mm(D)*1600mm(H) |

● |

|

|

1550mm(W)*700mm(D)*1600mm(H) |

|

● |

|

|

Power |

1P/220V/10A |

● |

● |

|

VAC |

-70KPA~-80KPA/0.5MPA |

● |

● |

|

Optical System |

Infinity Color Correction Optical System |

● |

● |

|

Observation method |

Bright field/Dark Field/Polarization/DIC |

● |

● |

|

Eyepiece |

High eyepoint wide field plan eyepiece PL10X/22mm, micrometer and adjustable diopter for optional |

● |

● |

|

Viewing head |

5-35° adjustable, erect image, tilting trinocular head, interpupillary distance: 50-76mm, splitting ratio R:T=100:0 or 0:100 |

● |

● |

|

Objectives |

Long working distance BD plan semi-apochromatic metallurgical objectives 5X/10X/20X/50X/100X |

● |

● |

|

Nosepiece |

Electric sextuple bright and dark field nosepiece, with DIC slot |

● |

● |

|

Microscope Body |

Reflected frame with low position coaxial focusing mechanism, coarse range: 35mm, fine precision: 0.001mm, with upper limit and tension adjustment. Built-in 100-240V wide voltage system. |

● |

● |

|

Illumination |

Bright and dark field illumination for reflected, with field diaphragm and electric variable aperture, with switch device of bright and dark field, with slots for filters and polarizing attachment, with 12V/10W LED lamp house |

● |

● |

|

Stage |

6 inches mechanical stage with low position coaxial adjustment. Wafer holder stage: Φ38mm, 360°rotatable. Moving range: 228mm(X)*170mm(Y). Observation range: 170mm*170mm. With clutch handle. |

● |

|

|

8 inches mechanical stage with low position coaxial adjustment. Wafer holder stage: Φ60mm, 360°rotatable. Moving range: 280mm(X)*210mm(Y). Observation range: 210mm*210mm. With clutch handle. |

|

● |

|

|

Others |

Filters |

○ |

○ |

|

Polarizer and analyzer |

○ |

○ |

|

|

DIC kit |

○ |

○ |

|

|

C-mount adapter |

○ |

○ |

|

|

Camera |

○ |

○ |

|

|

Professional software for wafer inspection |

○ |

○ |

Note: ● Standard Outfit, ○ Optional