948-II Soldering station

Introduction

Adopts PID programmable temperature control technology with an implant able highest-precision PID program for high-speed tracking and detection of actual desoldering gun and soldering iron temperatures with real-time temperature correction.

Details

Overview

Quick Details

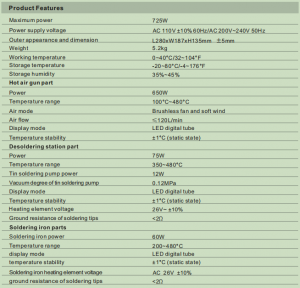

Maximum power725W

Temperature range 100°C~480°C

Display modeLED Digital Tube

Working temperature0~40°C/32~104°C

Storage temperature-20°C~80°C/-4°C~176°F

Storage humidity35%-45%

Weight5.2Kg

Dimension L280XW187XH135mm

Packaging & Delivery

Packaging Details:Strong Carton with Polyfoam Protection

Port:Beijing

Lead Time:Within 3-4 weeks after receiving payment

Introduction

1.Adopts PID programmable temperature control technology with an implant able highest-precision PID program

for high-speed tracking and detection of actual desoldering gun and soldering iron temperatures with real-time

temperature correction. Miraculous temperature compensation speeds allow for minimal temperature error for

temperature stability and compensation speeds.

2.With hot air gun rework station, desoldering station, soldering iron and suction pen functions, the rework range is

wide. The desoldering station and soldering iron functions are smart with interchangeable identity. With a handle

connected, such a function can easily be used.

3.Anti-static design prevents electrostatic component damage or leakage.

4.Built-in vacuum with strong suction and without an external vacuum system, easy to carry.

5.The design of machine has the following strong humanization functions:

A.With 3 storage function:Different parameters can be stored separately, it is convenient to choice, and easy

to operate.

B.Digital temperature correction function: You can use this feature to correct the temperature when the iron

temperature is different from the display temperature ,which caused by the environmental impact or replacing

heating element, iron tips or other components.

C.Temperature Celsius/Fahrenheit display function: This temperature

display mode designed to meet the needs of different markets, you can choose according to your customary or

interest.

D.Iron sleep function:Soldering iron automatic detection of their work status are not in use in a quiescent state,

arriving to set the sleep time, the temperature of the iron automatically lower the temperature to 200°C enter into

sleep state, can effectively prevent the oxidation of iron head and prolong the iron tip service life, energy saving

and environmental protection. The sleep time can be set range: 2 to 99 minutes in 1 minute steps, users can be

set based on usage, if you do not need a soldering iron sleep ,the sleep time is set to – – -.

Waking up hibernation method:

a.Shake soldering handle up and down several times or flflick the red switch on the suction gun once.

b.Press any one button.

c.Turn the power switch on and off.

E.Automatic shutdown function: After machine enter into sleep state, start the timer program, set the shutdown

time did not wake up from sleep, automatic shutdown, energy saving and environmental protection. Auto power off

time setting range: 2 to 99 minutes in 1 minute steps, If you do not need a auto shutdown function ,the power off

time is set to – – -.

F.Air gun without wind protection function: Non-normal stopping in the process of using a hot air gun, the

heating element will stop heating, it can prevent burn the handle, and greatly improved product safety.

G.Air gun automatic/manual function:

a.When you choose the Auto function, and the air gun handle back on the bracket, the machine will shut off the

heater automatically and cool down, it can prolong the service life of the heating element effectively and it is

energy saving and environment friendly. It has very high safe factors when turn on the machine again ,when you

turn on the machine at the an unknown condition. It can prevent the fifire or other accidents effectively.

b.When you choose the manual function, the air gun will not cool down when you put it back to bracket, this

function is suitable for using the air gun frequently, it can save the cooling and warming up time, improve the

working effificiency. We recommend you that after using the manual function, please transfer the function into auto

function, so it can improve the safety.

6.With a unique tin suction nozzle and heating pipe design, solder can be inhaled through fifilters in a molten state

without the need for regular maintenance, thereby delivering greater effificiency.

7.Adopts silicone heat-resistant tubing to prevent heat generation and contact damage.

8.The double-sided internal SMT manufacturing process boasts clean craftsmanship. The signal flflow is clear, and

the machine is both stable and safe, further improving its performance and adaptability to various harsh

environments.